Medical Device Coating

As part of our complete medical device manufacturing services, Galway Biomedical provides advanced braided implant coating technologies that are engineered to enhance the functionality, performance, and biocompatibility of medical devices. These specialised, impermeable barrier coatings can be precisely applied to both nitinol and polymer braids, ensuring optimal protection and consistent results. Our in-house surface treatment capabilities support short- and long-term medical implants using materials such as Silicone, PU, PU-Sil, and resorbables, while also developing innovative multi-layered systems with hydrophilic topcoats designed for both complex and standard device geometries.

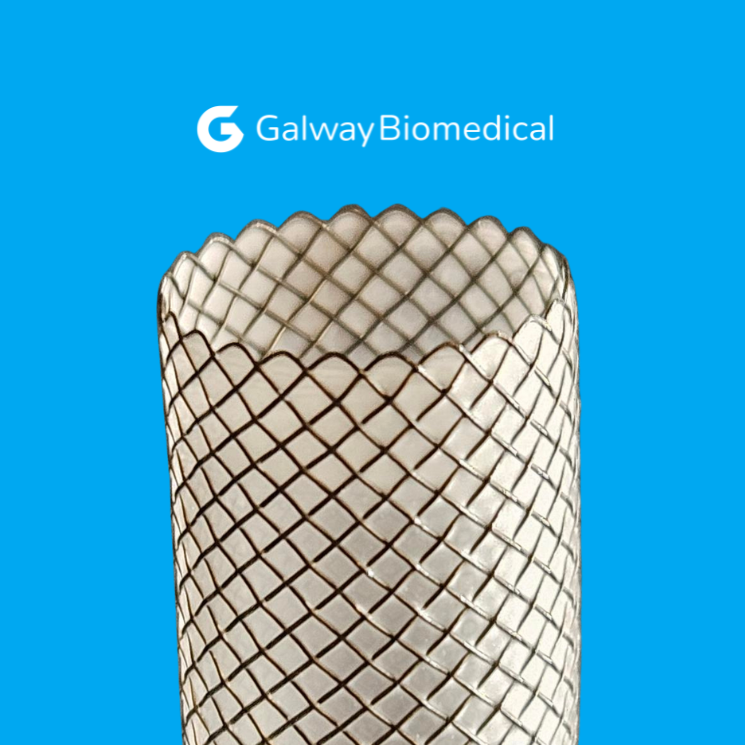

Dip Coating

Galway Biomedical possesses extensive expertise in precision dip-coating techniques for implantable medical devices, providing expert guidance to overcome the challenges of coating complex geometries and deliver consistent, high-quality results.

Wall thicknesses as thin as 10µm (0.0004”) can be achieved, with flexible membranes capable of spanning large open-frame structures. This advanced process can be applied to both discrete components and fully assembled devices attached to delivery systems.

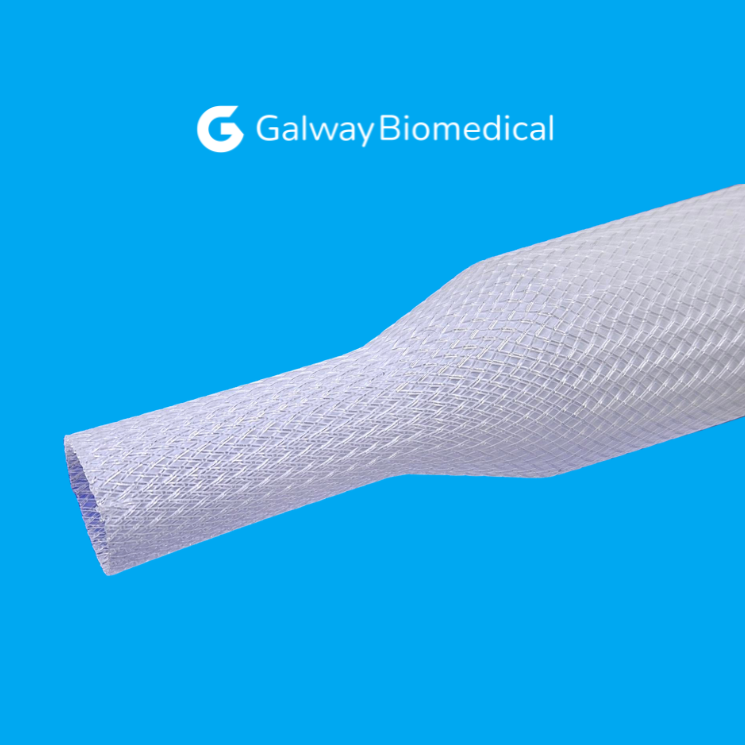

Lubricious Coating

Galway Biomedical applies advanced hydrophilic coating technology to create highly lubricious surfaces on implantable medical devices. These solutions are engineered to reduce surface friction, facilitating smoother implant delivery and deployment within the body. Additional benefits of these biomedical surface treatments include atraumatic device placement and improved tracking through complex or tortuous anatomies.

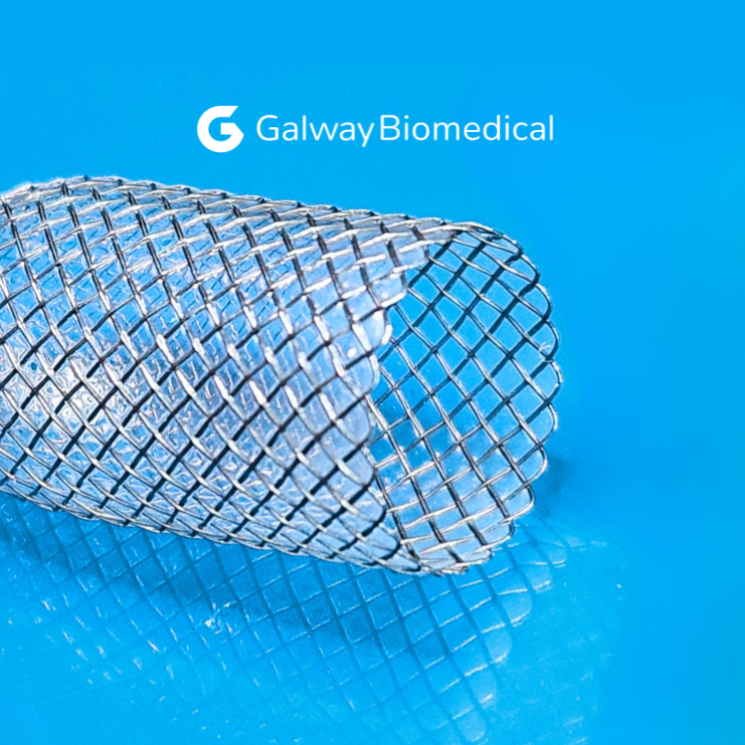

Elastomeric Coating

Galway Biomedical provides advanced elastomeric coating solutions designed that enhance flexibility, abrasion resistance, and biocompatibility for a wide range of medical devices. Experienced engineers carefully select appropriate material grades and chemistries, ensuring key mechanical properties - such as Shore hardness, Ultimate Tensile Strength, flexural modulus, tear resistance, and elongation - are optimised to meet the precise performance requirements of each coated medical device.

Work with Us

Galway Biomedical’s mission is to support clients seeking biomaterial based, low profile, complex and advanced braiding solutions.

Reach out to Galway Biomedical today to accelerate your project goals.

ISO 13485 Certified