Laser Processing

Galway Biomedical supports its clients with an array of fiber-pulsed and ultrashort-pulsed lasers supporting complex device geometries ranging from large, rigid heart valve frames to highly flexible and fragile neuro devices. Galway Biomedical applies skill, capacity and a range of laser technologies to shorten client time to market by utilising processes to create and refine prototypes with unparalleled speed.

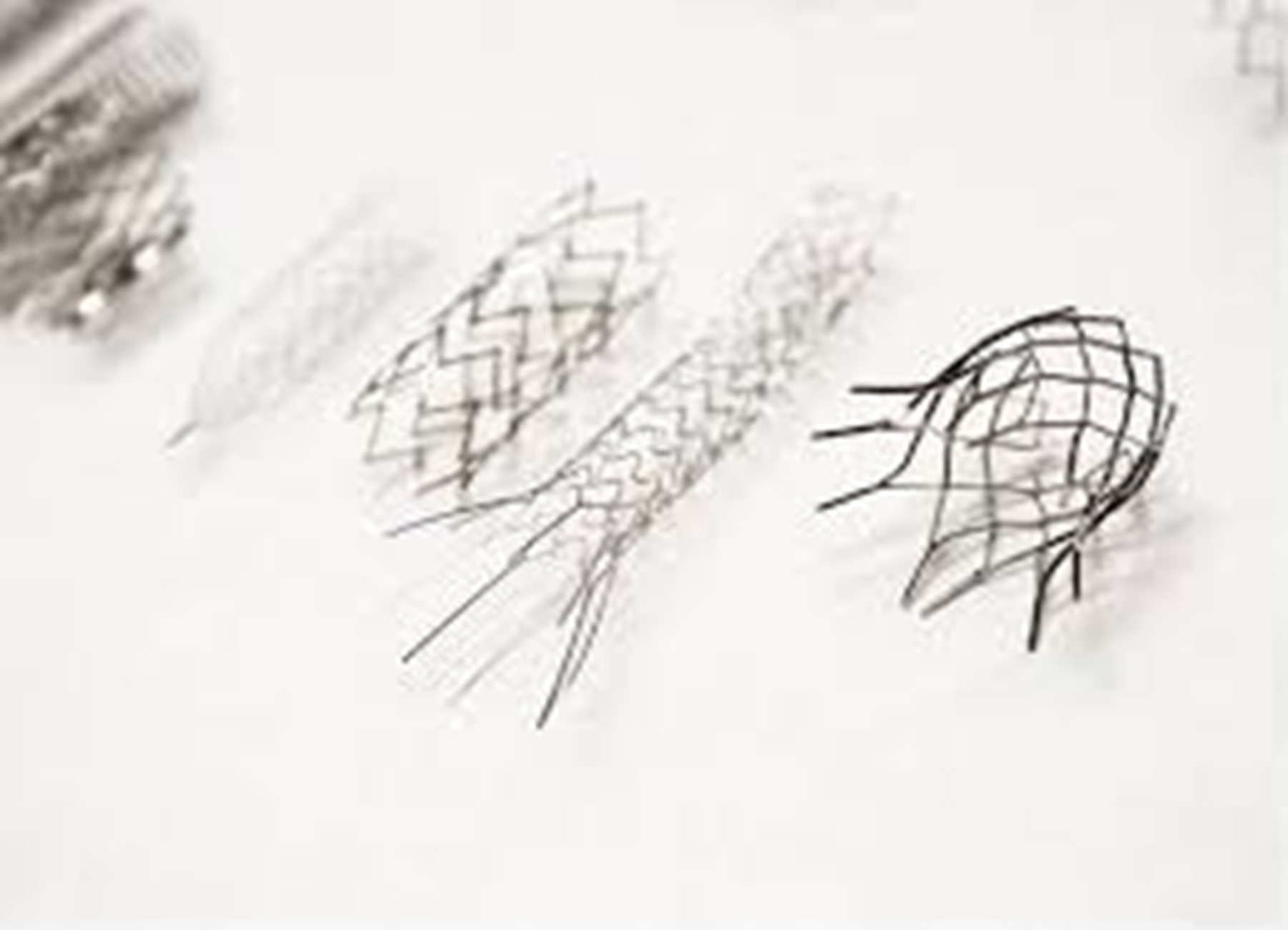

Nitinol Processing

- Material / Tube Selection

- Electropolishing

- Shape Setting

- Micro Waterjet Cutting

- Laser Cutting

- Braiding

Biomaterials

Galway Biomedical includes both metal and polymer biomaterials in its complex & advanced laser processing capabilities, leveraging an international supply network to source a wide range of implantable grade biomaterials.

Metal Laser Processing

The choice of material in a laser cut device significantly influences its mechanical properties. For medical laser processing applications Galway Biomedical utilizes a variety of round and flat wires, including:

- Stainless Steel: 316L medical (316LVM)

- Cobalt Alloys: L605, Phynox, MP35N

- NiTi (Nitinol)

- Magnesium

- Nickel-free

Polymer Laser Processing

For laser processed medical applications Galway Biomedical utilizes a variety of non-resorbable biocompatible materials, in both mono and multi-filament configurations, including:

- Ultra-High Molecular Weight Polyethylene (UHMWPE)

- Polyester (PET)

- Nylon

- Polypropylene (PP)

- PTFE

- Liquid Crystal Polymer (LCP)

Resorbable Polymer Laser Processing

Galway Biomedical’s expertise encompasses the preparation, processing and post-processing of resorbable materials. Some of the common resorbable materials utilised include:

- Polydioxanone (PDO)

- Polyglycolic Acid (PGA)

- Polylactic Acid (PLA, PLLA)

- Polycaprolactone (PCL)

- Polylactide/Glycolide Copolymers (PGLA)

- Magnesium

Bespoke Material Laser Processing

Galway Biomedical offers laser processing for bespoke, patented materials owned by clients. If you don’t see your desired material listed above, please reach out for an assessment of your material's compatibility with Galway Biomedical’s production equipment.

Finishing

Automated passivation, neutralization, and surface cleaning for consistent results. Exceptionally smooth surfaces and excellent corrosion resistance.

Shape setting allows for components to be moulded into distinct and complex configurations. The device can then be crimped for low profile delivery, expanding into the preformed shape upon deployment.

Packaging is offered in line with client’s requirements in an ISO Class 7/8 cleanroom. This includes packing for sterilisation, label production and full production traceability.

Following early stage prototype feasibility, process optimisation stages and manufacturing transfer, Galway Biomedical offers medical device volume manufacturing.

Work with Us

Galway Biomedical’s mission is to support clients seeking biomaterial based, low profile, complex and advanced braiding solutions.

Reach out to Galway Biomedical today to accelerate your project goals.